BCG Configuration FAQs

Answers to common questions regarding configuring Bulk Calculations – Gas (BCG) on your systems

Which conversion group should I use for my high pressure pipeline natural gas project?

For high pressure natural gas projects, an MQCI conversion group should be selected. A certified BCG consultant can access the Gas Measurement Cockpit (GMC) and will follow the PAIG Methodology in order to create a selection of template conversion groups. The correct choice then depends on the detailed calculation scenario requirements which you will discuss with the certified consultant.

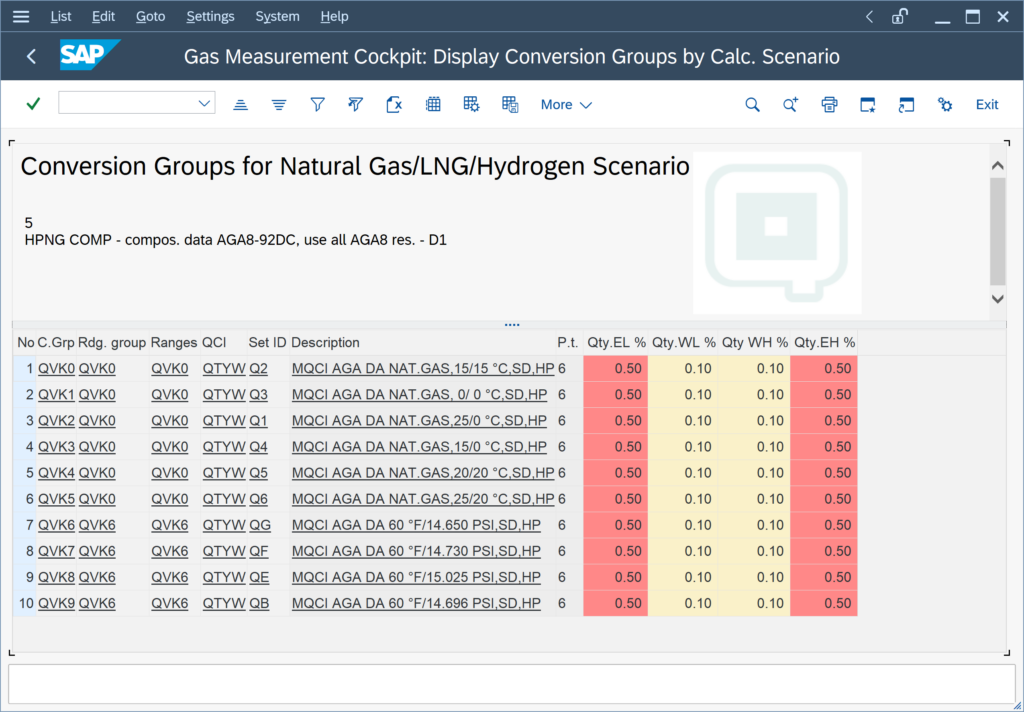

Example:

Template selection of high pressure conversion groups for AGA Report No. 8 / ISO 6976 calculations:

Does QuantityWare BCG support hydrogen quantity conversions?

Yes.

Due to strong industry demand, QuantityWare has defined a development strategy for 100% hydrogen quantity conversions, which is published in note 000106. See the BCS Supported Products Manual for this new product support.

Read the FAQ for natural gas / hydrogen mixtures for support of natural gas – hydrogen mixtures, which are also supported.

The first release of a 100% high pressure hydrogen quantity conversion solution – as part of QuantityWare BCG 3.0 – has been delivered as an Advanced Development (AD) with note 000100 in July 2022,

We are processing natural gas with a high hydrogen fraction, but not 100% hydrogen. What conversion groups can we use for such a gas?

As stated in the research paper from the DVGW: “Calculation of Compression Factors and Gas Law Deviation Factors Using the Modified SGERG-Equation SGERG-mod-H2”

“The AGA8 equation and the GERG-2008 equation generally agree better than ± 0.1% for the measured values for all data sets in the entire pressure range. It can thus be expected that these equations of state can be used for any desired H2 fractions without significantly affecting the underlying 0.1% uncertainty of the equations.”

Thus, BCG conversion groups that are configured to utilize AGA8 compression factor calculations may be utilized for natural gas / hydrogen mixtures of any ratio.

I require UoM gigawatt hours for my natural gas calculations, how do I define it?

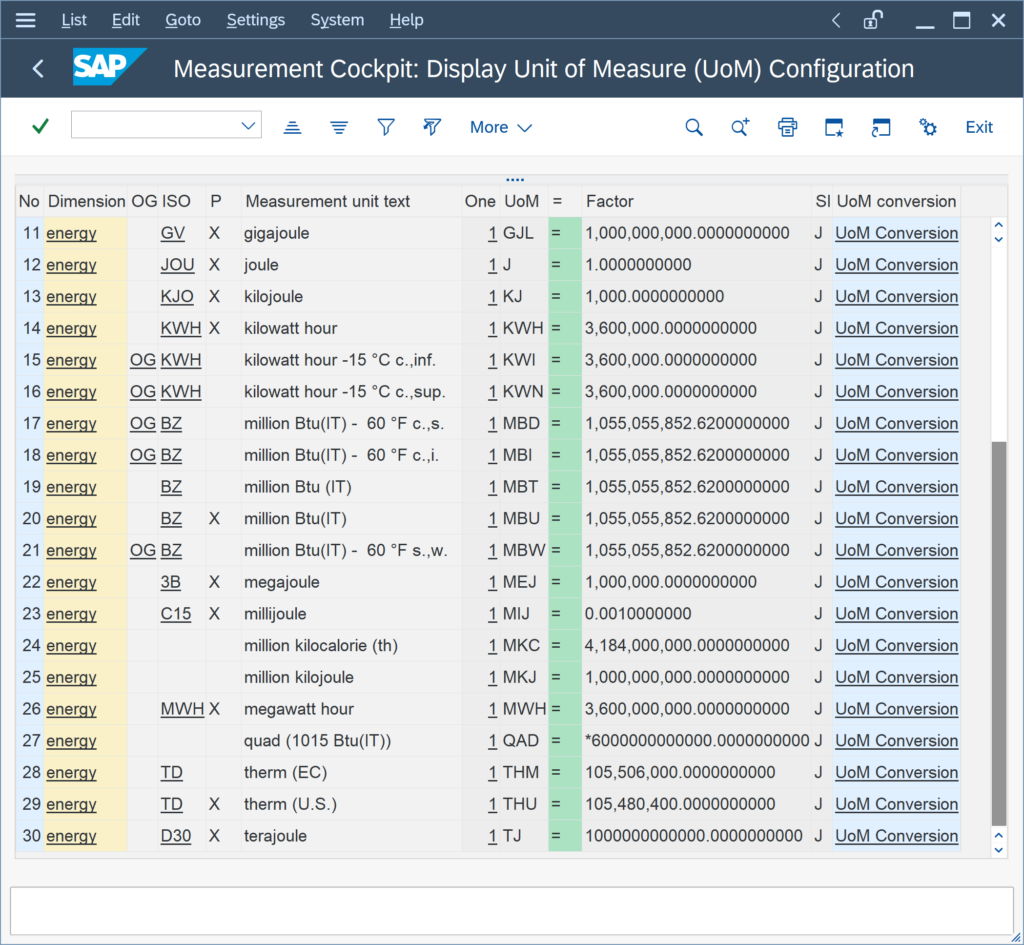

Gigawatt hour is an energy UoM. As part of the QuantityWare configuration template (BC sets), 30 energy UoM are delivered:

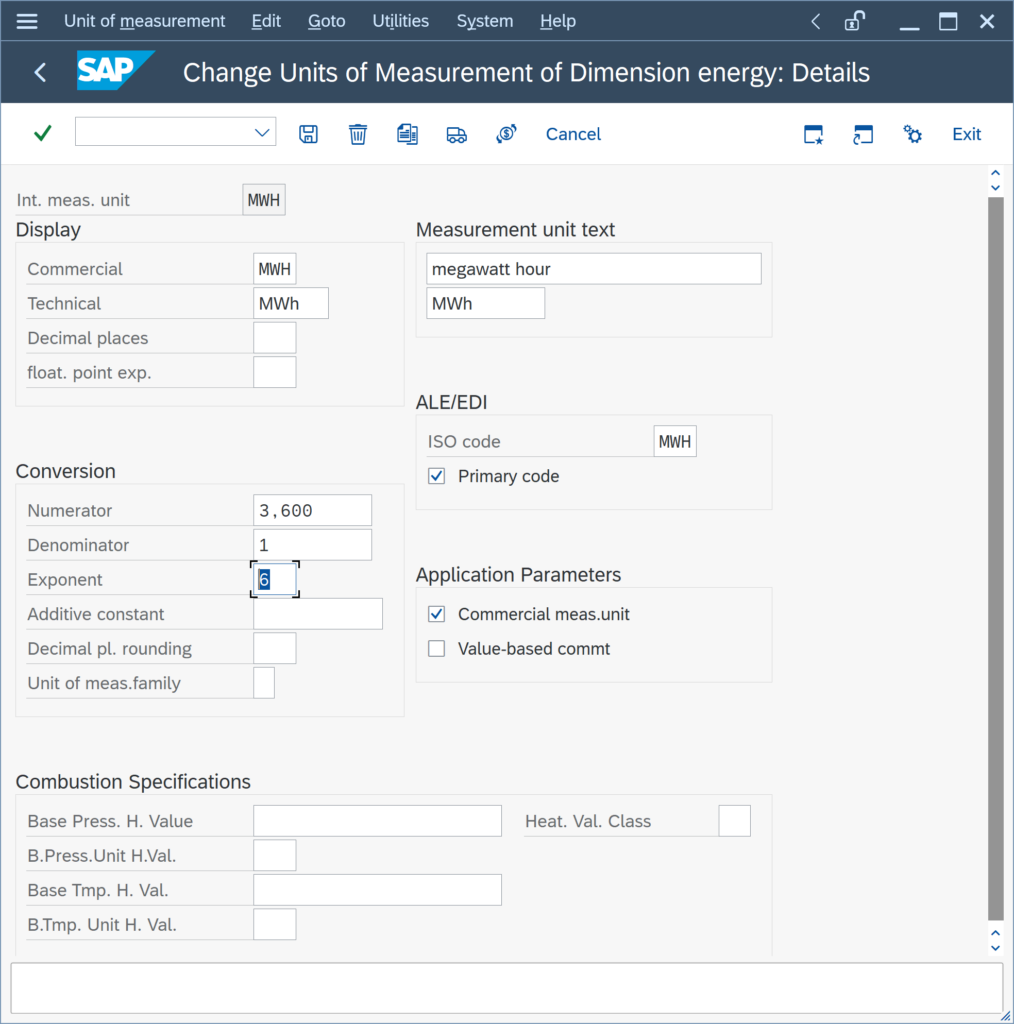

Gigawatt hour and terawatt hour are not defined in historic templates. However, these UoM can be added easily to the template and then distributed through your system landscape. Simply copy e.g. UoM MWH (megawatt hour):

to GWH and TWH, and adjust the exponent in the details from 6 to 9 (GWH) / 12 (TWH). Check with business experts if a combustion condition set is required – typically natural gas quantity conversions do require specification of a combustion reference temperature:

With BCS 30A CSP03 / BCS 30B CSP02 four new energy UoM,

Which conversion group should I use for my LNG project?

For LNG projects, an MQCI conversion group should be selected. A certified BCG consultant can access the Gas Measurement Cockpit (GMC) and will follow the PAIG Methodology in order to create a selection of template conversion groups. The correct choice then depends on the detailed calculation scenario requirements which you will discuss with the certified consultant.

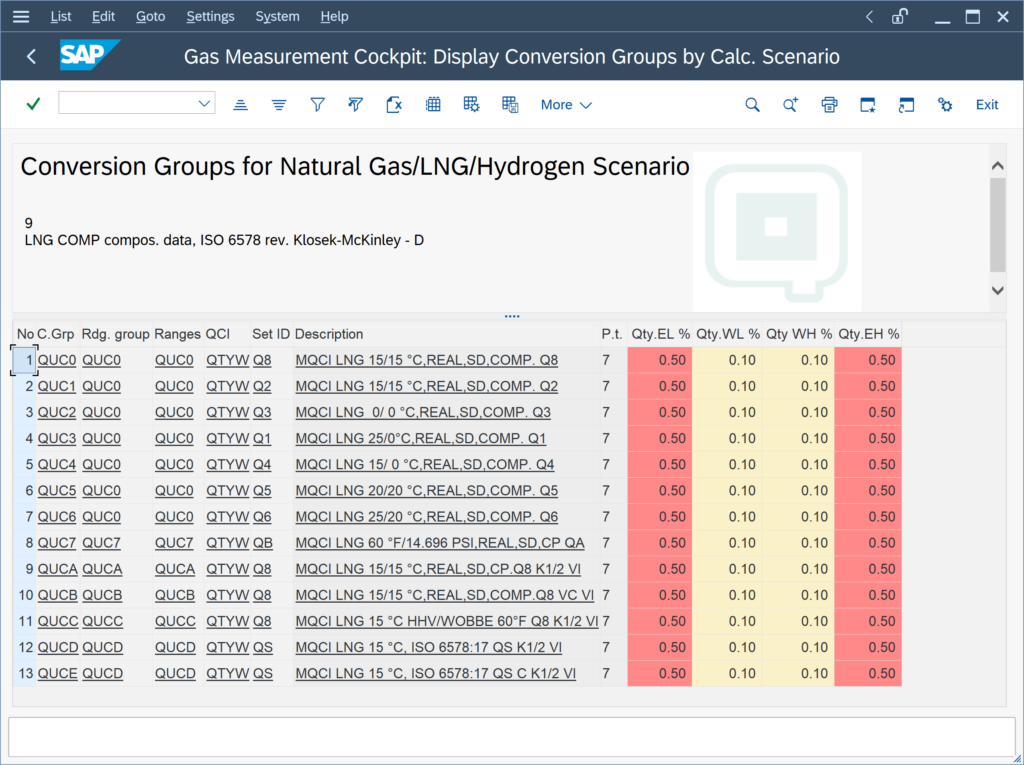

Example:

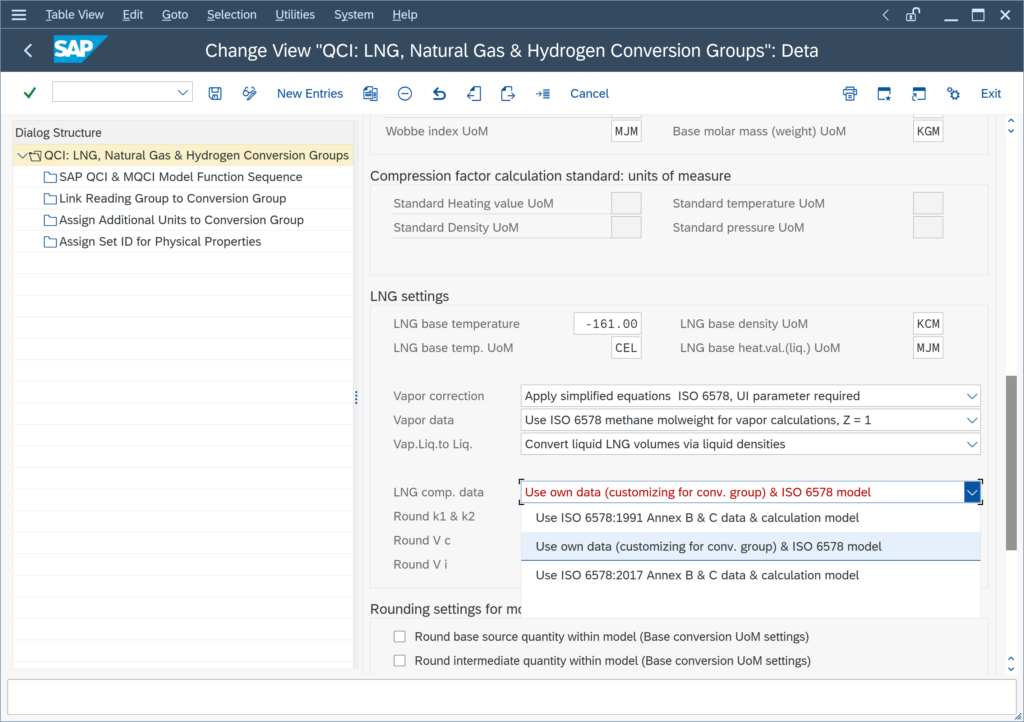

Template selection of LNG conversion groups for detailed ISO 6578 LNG calculations:

What options do we have for ISO 6578 LNG density calculations from composition?

QuantityWare BCG supports the ISO 6578 (Version 1991 and 2017) density calculations for LNG. As described in Note 000076, the main difference between these two versions is the definition of configuration data, i.e. the k1 and k2 factors and orthobaric molar volumes. Customers may wish to utilize their own, contractually defined, calculation data sets.

NOTE: This is a critical task for any LNG implementation, thus a certified BCG consultant is required to support this task.

You have three options to define the density calculations:

- Utilize ISO 6578:1991 data –

My LNG volumes in SAP Tank Management are way to large, how can this be?

As capacity UoM, the tank master data in SAP Tank Management (transaction O4NA) requires usage of a UoM of dimension VOLUME. Thus, you define e.g. M3 (cubic meter, m³) as capacity UoM.

If you now perform a tank dip, utilizing your strapping data values in M3, the mass and energy quantity values calculated by the system are too small when compared to the apparent liquid LNG M3 value calculated from strapping – or, the volume quantity value in M3 (or any other UoM of dimension VOLUME) appears to be too large in relation to the mass quantity values and energy quantity values.

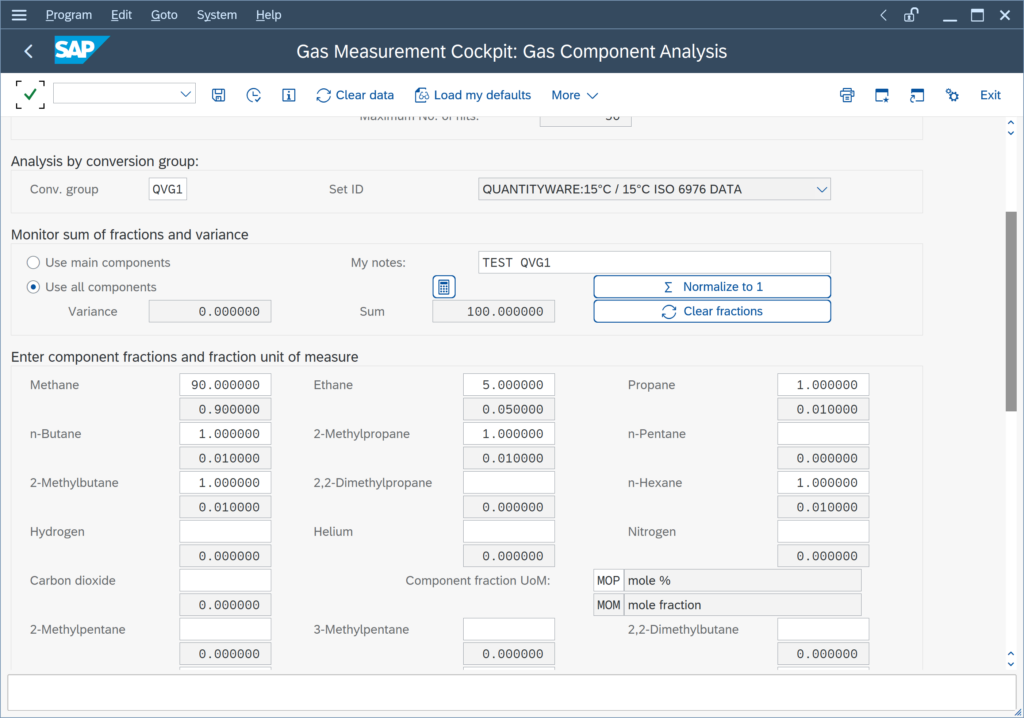

Why are there no chemical components for i-butane and i-pentane defined in the gas component analysis?

You enter the chemical composition data for a material or conversion group into the gas component analysis. However, there are no fields for i-butane (isobutane) and i-pentane (isopentane). Why?

i-butane and i-pentane are synonyms for the components 2-methylpropane and 2-methylbutane (the preferred IUPAC name), i.e. i-butane is 2-methylpropane and i-pentane is 2-methylbutane.

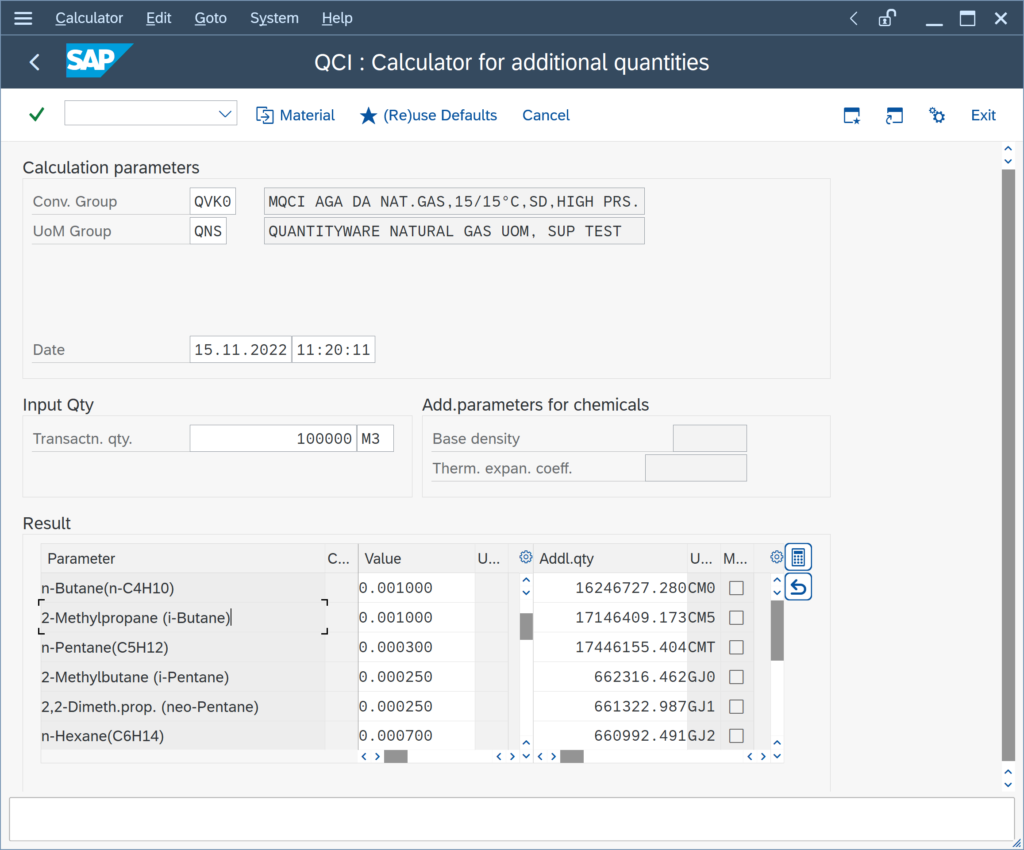

Some template conversion groups contain this mapping in the reading group parameter description, e.g. QVK0:

We enter pressure values for gas calculations. Are these values absolute or gauge pressure values?

QuantityWare BCS implementations for LPG/NGL, LNG and natural gas support both the data entry of absolute or gauge pressure values. Crude oil and products CPL calculations do require entry of gauge pressure values.

The conversion group configuration for LPG/NGL, LNG , natural gas, crude oil and products can thus be made to support entry of either gauge or absolute pressure values – by adding or removing dedicated MQCI pressure calculation functions to the conversion group function module sequence.

I enter a vapor pressure value in bar, and it is converted to the value in kPa, why is that?

For pressure value data it is important to differentiate between absolute pressure values and gauge pressure values.

For all conversion groups, that are configured to require entry of pressure values, these values can either be a gauge or an absolute pressure value.

The behavior described in this FAQ question is defined within dedicated MQCI pressure conversion functions, that convert gauge pressure values to absolute pressure values – visible to the user and using the base pressure UoM as absolute (or vice versa).

If you do not require this behavior, you may replace the MQCI pressure conversion function with the corresponding function that treats all UoM as either all absolute or all gauge values,

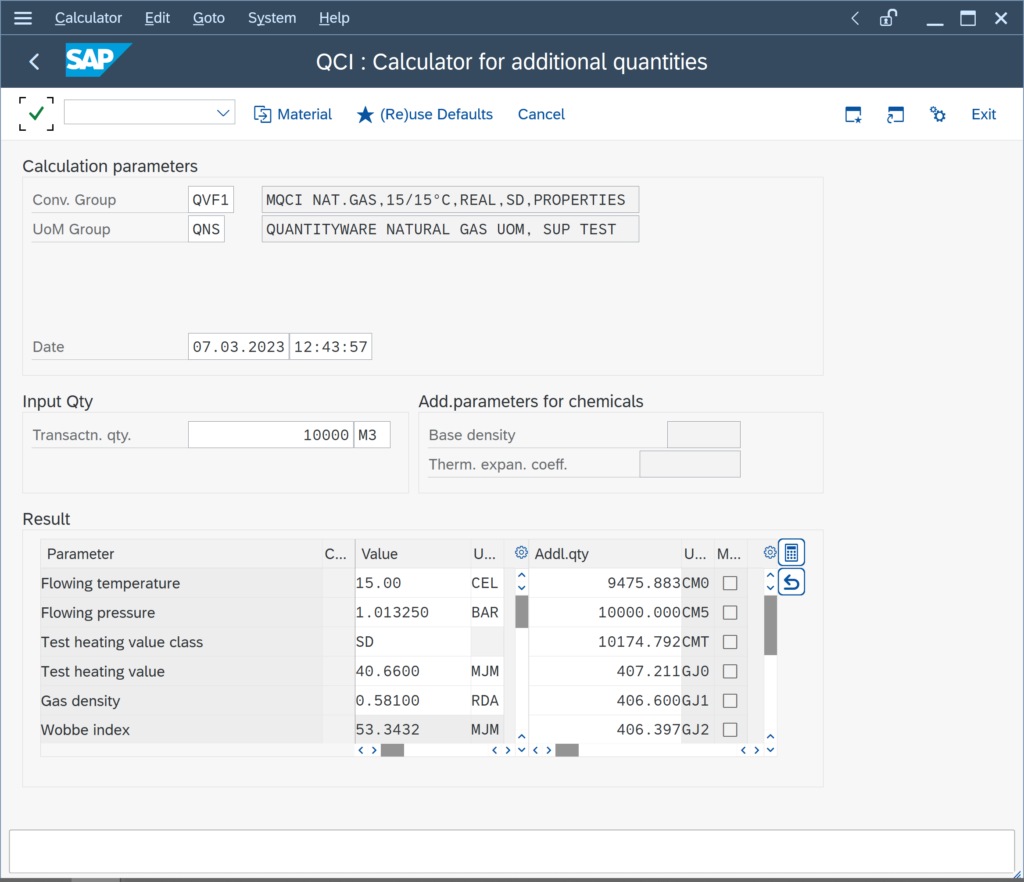

We receive error message /QTYW/BCG 114 - Heating value class is initial. How can we resolve this issue?

You perform quantity conversion calculations utilizing MQCI natural gas or LNG conversion groups. You receive error message /QTYW/BCG 114 – Heating value class is initial, enter a valid heating value class.

This message does not explain why the calculation is not completing. It actually appears, if the transaction UoM or any target UoM is not of an allowed SAP dimension ID – Energy, Volume, Mass (or Volume(Liquid, LNG)) for LNG and natural gas.

Example: Test calculation for high pressure natural gas:

The calculation is executed successfully. Now change the transaction UoM to M3L,

Can we have one LPG/NGL conversion group, that either performs a static vapor space tank dip calculation or a CPL&CTL dynamic calculation for pipeline LPG?

Yes.

This is in principle possible.

However, one important fact to consider is that vapor pressure values are required as absolute values for the vapor space calculation, whereas observed/flowing pressure values may be required as gauge values for the CPL calculation.

Therefore, no standard MQCI pressure correction function may be assigned to such a conversion group (which all assume that both values are either both gauge values or both absolute values).

Thus, a detailed specification of this requirement must be available to a certified BCP or BCG consultant, who then performs a feasibility analysis with QuantityWare experts.

I have set my quantity value UoM L15 and KG to be rounded to zero decimals, but it is not working. What can I do?

The UoM real rounding settings are considered for all MQCI conversion groups (where rounding function

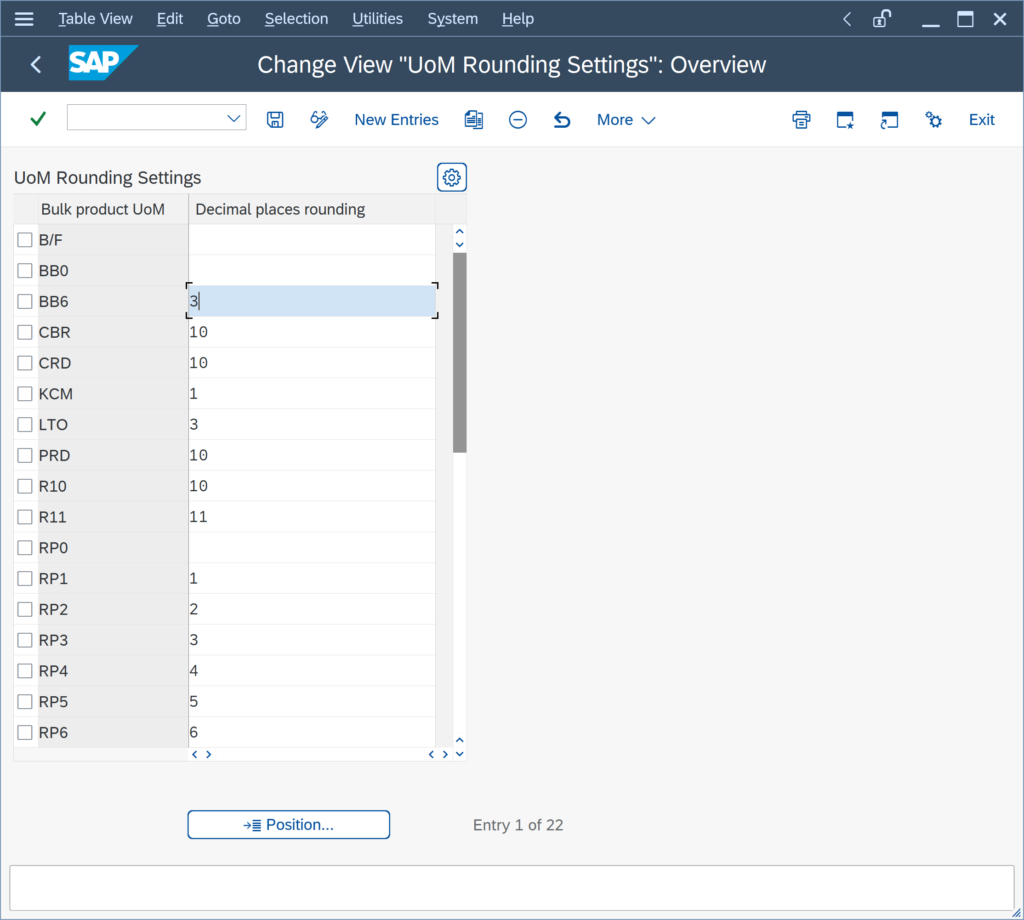

/QTYW/MQCI_ROUND_ALT_QUANTITYis assigned). To define the real rounding for a UoM, go to the PMC or GMC and navigate to: ( More -> ) Goto -> UoM Rounding:

and maintain the number of decimals for each UoM that shall be rounded.

NOTE: In the main UoM transaction CUNI, you define the number of display decimals for your UoM only – Read FAQ Display UoM for additional details.

How can I extend the density and temperature range for my product?

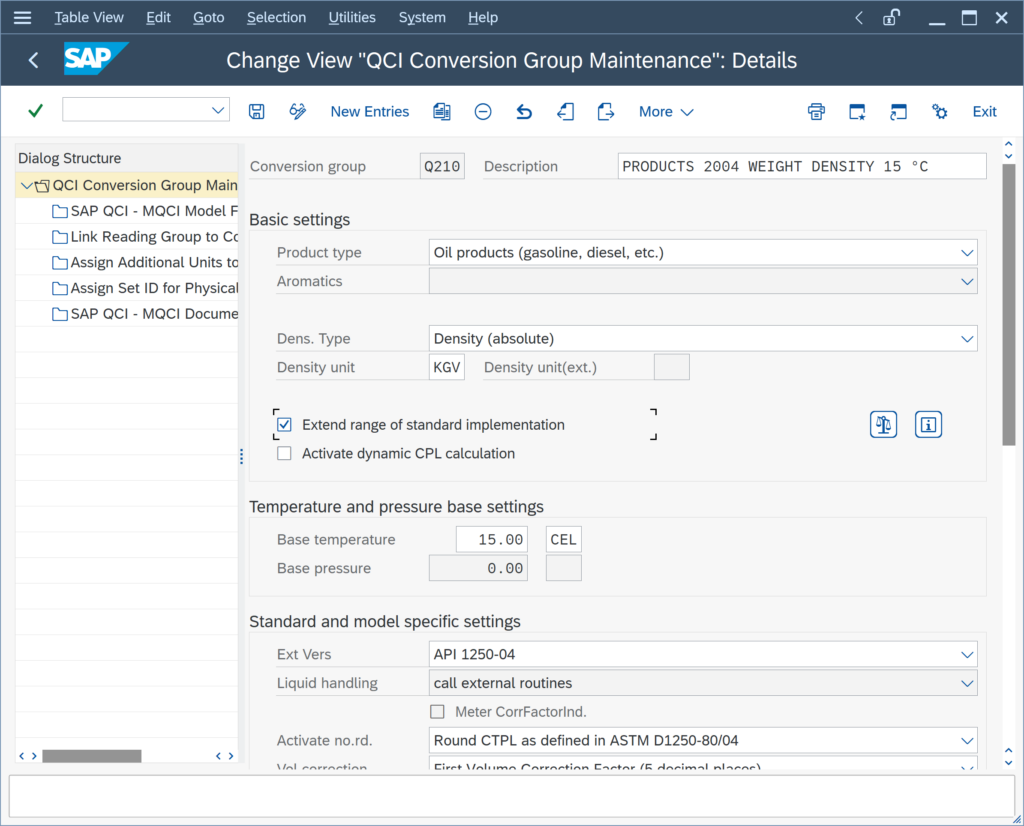

If you have a product which has a base density beyond the supported measurement standard range, or if temperature values are beyond the standard ranges, it is possible to extend the calculation range with one click:

This is possible for QuantityWare BCP ASTM D1250-80 and ASTM D1250-04 implementations, as well as for other standards – if the algorithm defined in the measurement standards allows so.

Then, you simply extend the range for densities, pressures and temperatures by selecting the “Extend range of standard implementation” indicator in the conversion group details screen:

Read Annex D: Standard Range Limit Extensions in the BCP Supported Standards Manual for additional information.

What is MQCI function /QTYW/MQCI_SYNC_EXT_VALUES good for?

BCS contains function /QTYW/MQCI_SYNC_EXT_VALUES, which you can decide to add to your MQCI conversion group configuration. This function detects quantity value data passed from external systems (via the “manual entry indicator”) to the SAP system. It then synchronizes dependent quantity values based on that data.

This synchronization – i.e., keeping related quantity values consistent – is an important part of the two main roles that QuantityWare BCS fulfills: The “Gatekeeper” and the “Enricher” role.

All QuantityWare MQCI template conversion groups are configured such that the MQCI function module sequence contains function /QTYW/MQCI_SYNC_EXT_VALUES as default.