BCG & BCP Configuration FAQs

Answers to common questions regarding configuring bulk calculations for LPG / NGL products on your systems

Does QuantityWare BCS support LPG and NGL?

Yes.

Details can be found in the BCP Supported Standards Manual, Appendix B.1. or the BCG Supported Standards Manual, Appendix A.2.

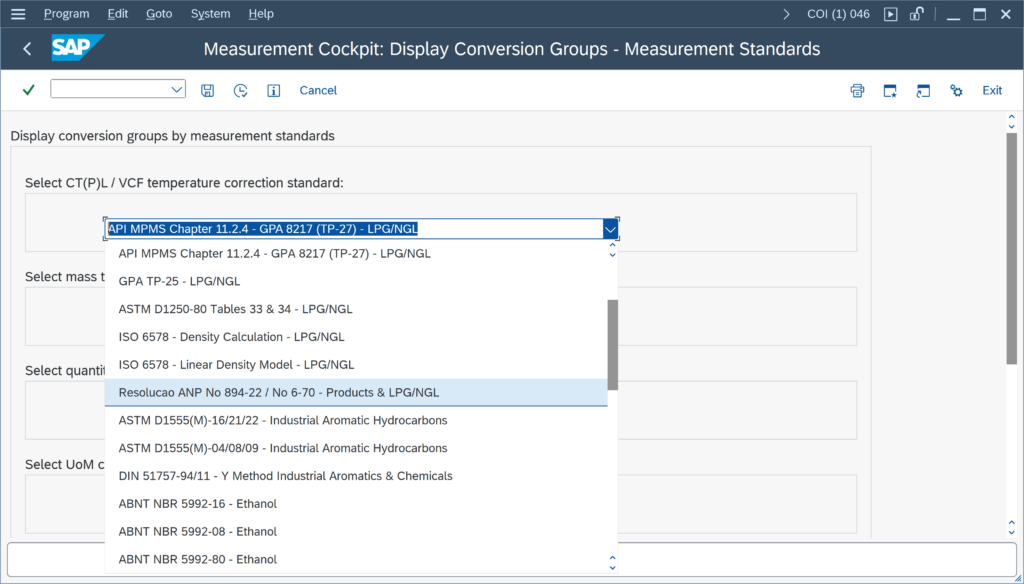

Via the PMC or GMC, LPG / NGL template conversion groups can be found in your reference client 045:

Read the LPG and NGL Difference FAQ for additional important details.

What is the difference between LPG and NGL?

- From a BCS measurement standard point of view (considering the basic thermodynamical properties of temperature, density, pressure / vapor pressure) , LPG and NGL (high vapor pressure) are identical, covered by the same group of supported BCS measurement standards*.

Thus, either a BCG or a BCP license** is required for quantity conversions of LPG and NGL, but not both. - From a business point of view, taking into account the LPG or NGL financial value, there are considerable differences:

- In a nutshell,

How do I use LPG vapor space calculations to determine the amount of LPG transferred?

When transferring LPG, we need to accurately measure the amount transferred. To do this, we make use of LPG vapor space calculations.

The video below describes the details of LPG storage, along with details of how to perform static LPG vapor space calculations using both transferred mass calculation and movement analysis methods, via QuantityWare’s Bulk Calculations Solution (BCS):

Vimeo Video

This video is stored on Vimeo. When you play this video, cookies are stored on your computer and data may be transferred to Vimeo, including IP address and cookie, this page URL,

We utilize an LPG conversion group with vapor space calculations. Why is the vapor mass not considered for volume UoM?

Vapor space calculations are defined in measurement standard ISO 6578. The calculation simply adds the vapor mass (and vapor energy or weight) to the appropriate liquid mass, energy and weight quantity (in any given UoM).

Volume quantity values are not updated with the liquid volume quantity value equivalent to the vapor mass and thus do contain the liquid product quantity value only (in any given volume UoM).

Therefore, it is important that the base UoM in the SAP material master is either a mass, weight or energy UoM.

Read the working paper “LPG vapor space calculations”

How are the two reading group indicators defined, that control the LPG vapor space calculations?

LPG quantity conversions support two vapor space scenarios. For each scenario, one indicator is relevant.

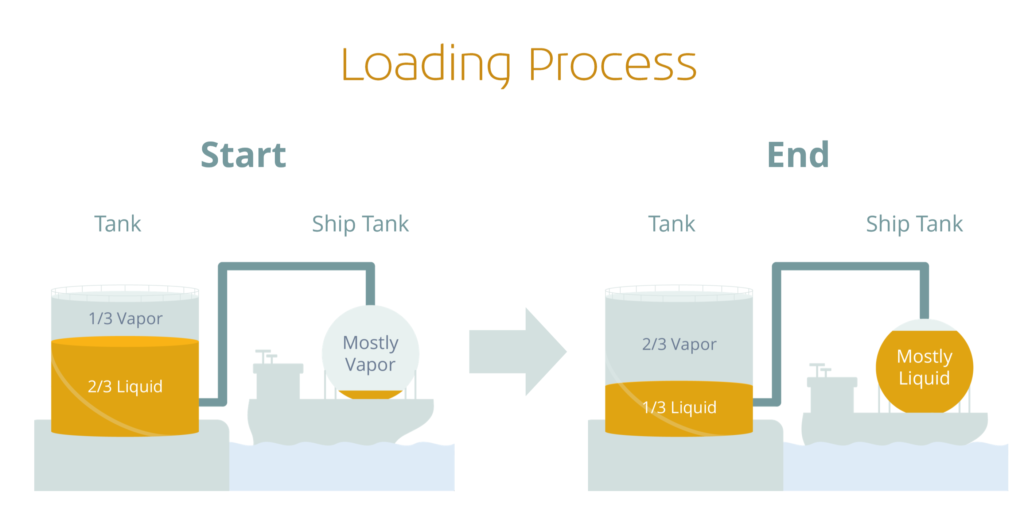

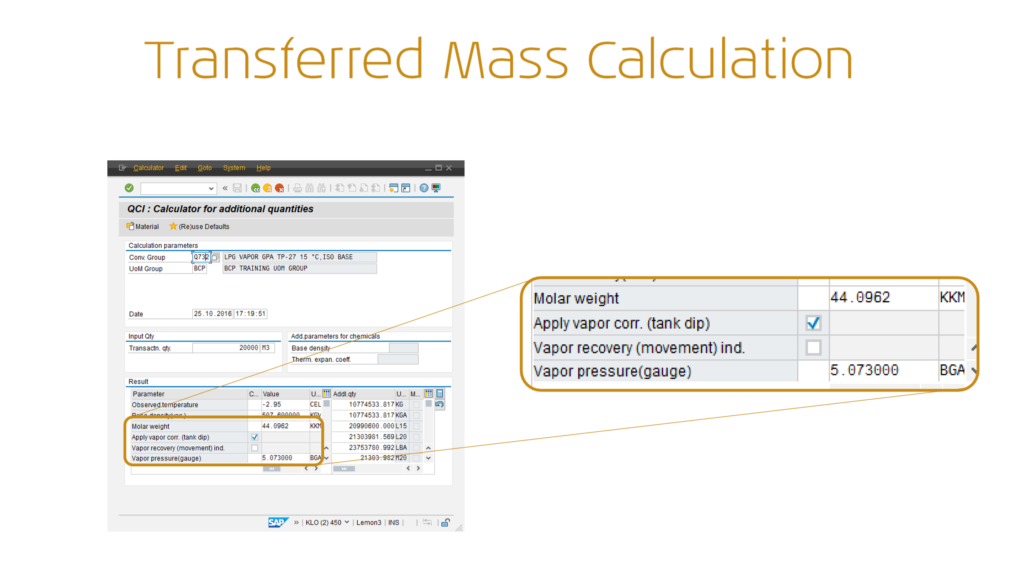

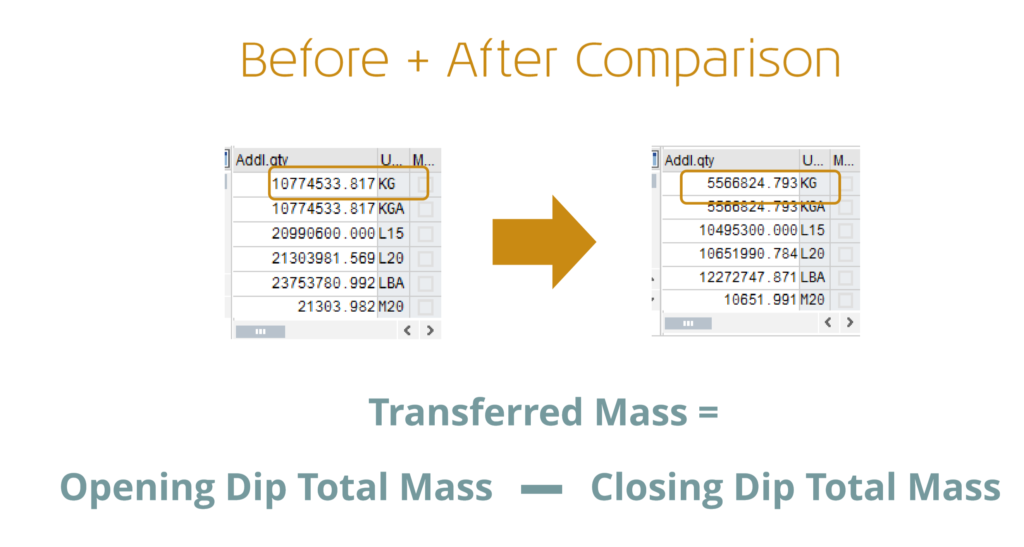

Scenario A: You perform an opening and a closing dip measurement (e.g. for a loading process shore-to-ship) to determine the transferred mass of LPG (e.g. by using SAP Tank Management and implementing your delta calculation logic in a SAP Tank Management BAdI):

Summary: In this scenario, you perform two calculations (opening and closing dip calculation) with the “Apply vapor corr. (tank dip)” indicator set. The transferred mass is calculated by subtraction.

Can we combine an LPG vapor space model with any product, not just classic LPG products?

Yes.

The QuantityWare BCS template contains many examples for GPA 8217 and ISO 6578 in combination with one of the three available LPG vapor space models. Any of these three models can be combined with any other meaningful CTL standard.

This makes sense for products with a vapor pressure above standard atmospheric pressure at reference conditions, e.g. national measurement standards for LPG or bulk chemical products.

In order to utilize an LPG vapor space model for other CTL standards, MQCI function

/QTYW/MQCI_SET_CTPL_TANK_VAPOR

must be included into the configuration of your conversion group,

Can we calculate LPG total volume (vapor plus liquid) quantities?

Yes.

This is possible via a Generic Customer Development (GCD).

QuantityWare BCS MQCI conversion groups for LPG/NGL may be configured to calculate total masses, energies and weights, as defined in ISO 6578. Total volume calculations are not part of the standard BCS delivery.

With note 000098, a generic customer development (GCD) is made available, which enables such calculations, utilizing an API MPMS Chapter 14.8 formula approach.

QuantityWare Certified Consultants (QWCC) have access to this GCD via the Support Portal.

I receive error message /QTYW/QCI091: Liquid LPG volume is negative; tank almost empty, correct measurements - why is that?

For LNG, NGL and LPG, you may require vapor space calculations. You utilize the static tank dip measurement indicator, such that the vapor mass (and possibly weight and energy) is calculated and added to the total mass (and possibly corresponding total weight and total energy):

Example:

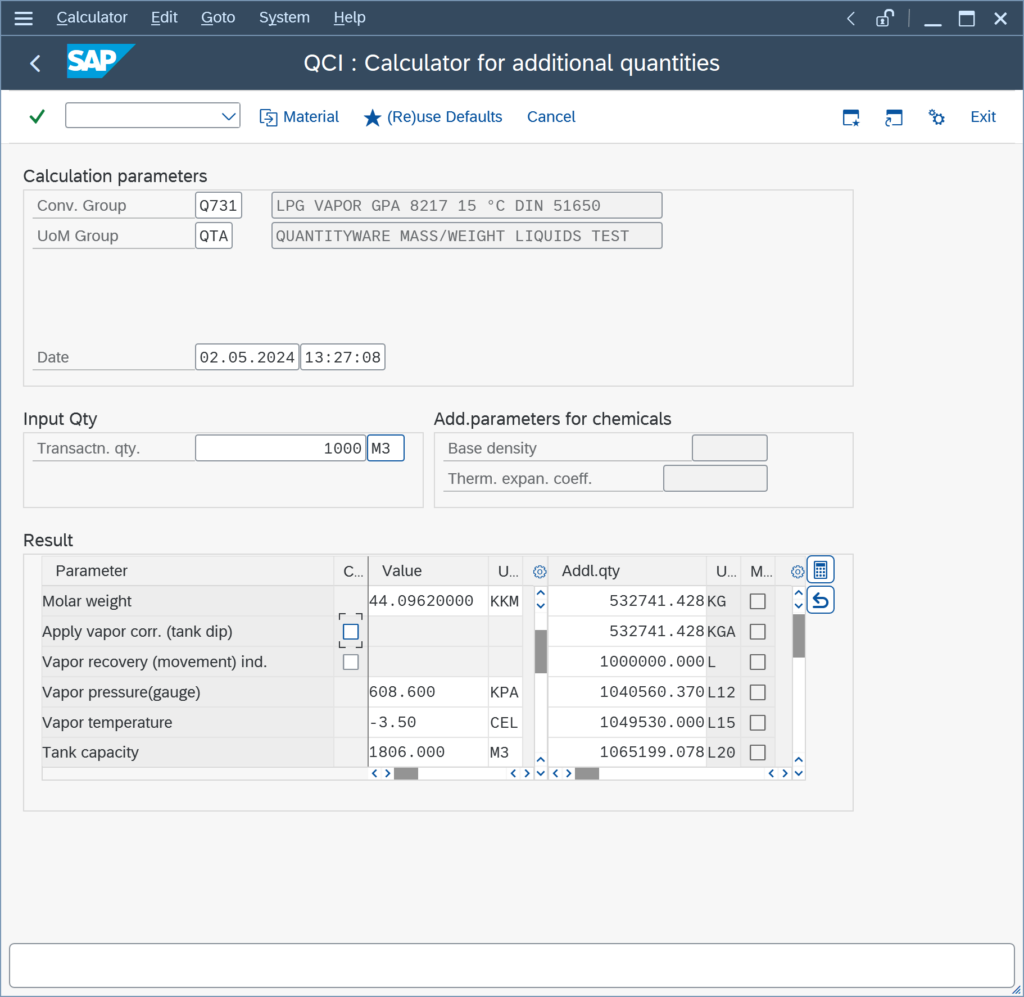

You measure 1 000 m³ of liquid product being in your tank; but you do not apply the vapor space calculation:

The mass of the liquid is thus calculated to be 532 741.428 kg.

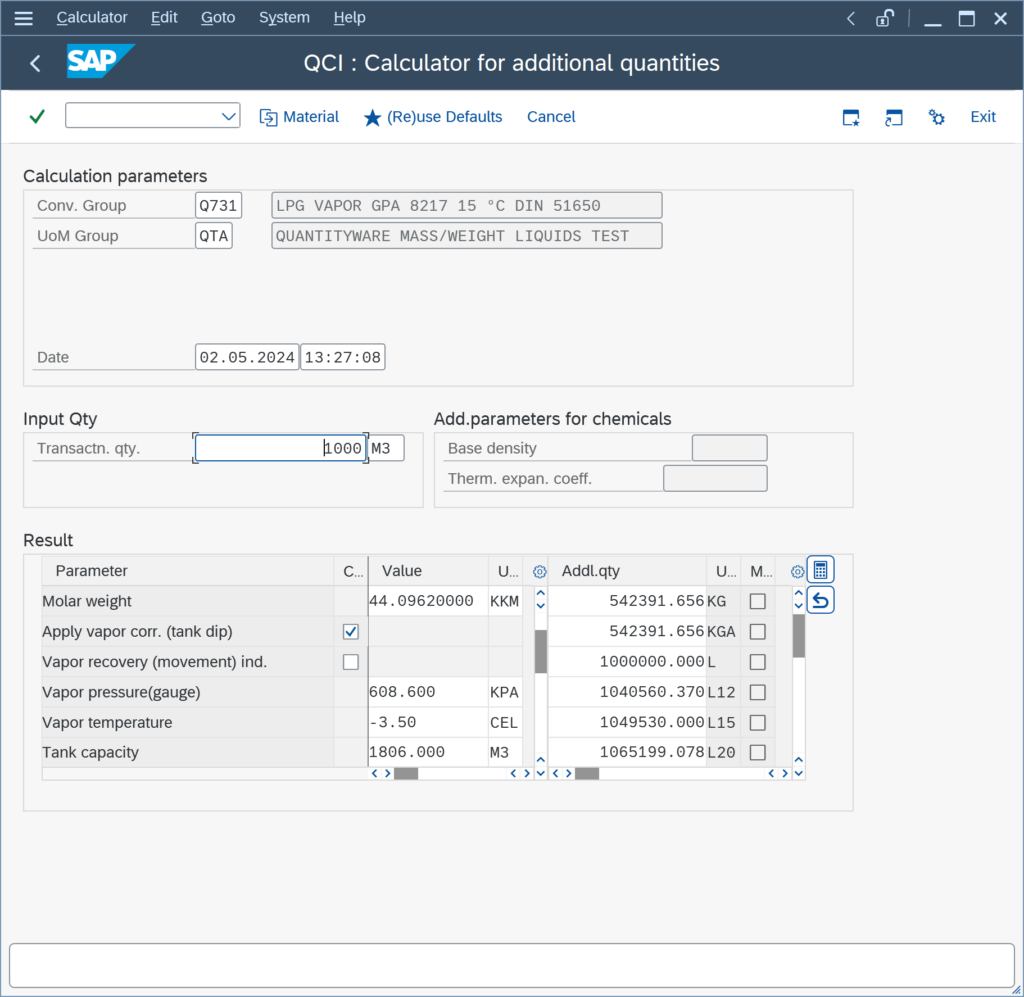

Now you set the vapor space indicator and perform a second calculation:

The total mass is now calculated to be 542 391.656 kg,

Can we have one LPG/NGL conversion group, that either performs a static vapor space tank dip calculation or a CPL&CTL dynamic calculation for pipeline LPG?

Yes.

This is in principle possible.

However, one important fact to consider is that vapor pressure values are required as absolute values for the vapor space calculation, whereas observed/flowing pressure values may be required as gauge values for the CPL calculation.

Therefore, no standard MQCI pressure correction function may be assigned to such a conversion group (which all assume that both values are either both gauge values or both absolute values).

Thus, a detailed specification of this requirement must be available to a certified BCP or BCG consultant, who then performs a feasibility analysis with QuantityWare experts.

Which chemical components can I add to an ISO 6578 LPG reading group?

ISO 6578 provides two density calculation methods for LPG density calculations, based on the known chemical composition of the LPG. Very large factors may have to be applied for the correction of observed density to density at standard temperature, e.g. a correction for the effect of a temperature difference of 60 °C may be necessary for refrigerated propane. Provided that the LPG does not contain more than 20 % of unsaturated hydrocarbons, the correction tables introduced in ISO 91 shall be used for volume corrections. Thus, ISO 6578 is intended for LPG products that contain more than 20 % of unsaturated hydrocarbons (e.g.

Our LPG conversion group does not allow entry of a test temperature to correct the LPG density to base. How can we solve this requirement?

Many of the MQCI LPG Q7** template conversion groups (as well as many crude oil and product Q2**/ Q1** and some linear DCF conversion groups, e.g. Q0A9) are configured such that the product base density (in vacuo or for DCF calculations – in air) can be entered directly without a need to enter a second so-called test temperature to correct a test density to base. This is described in more detail in the BCP Reference Manual, Chapter 6.10.

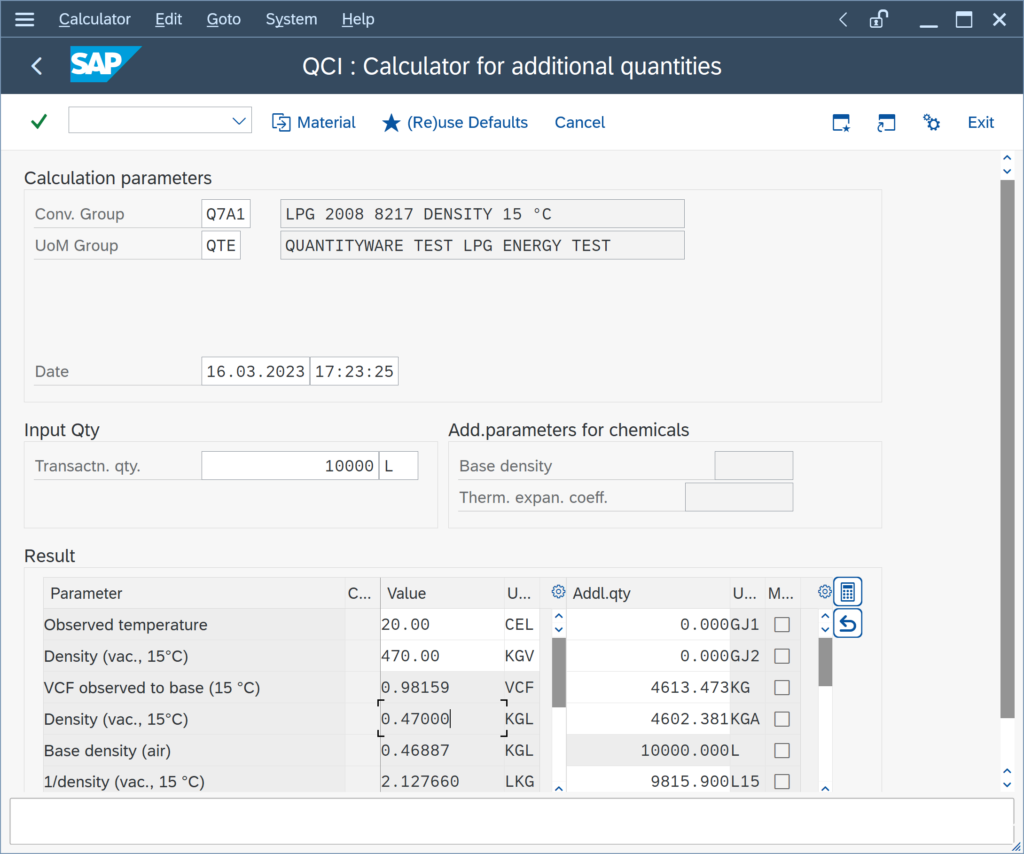

Example:

If required, you can extend your LPG reading group and add the test temperature (technical name OBSTSTMETT) and then also change the name of the input parameter OBSTSTDENS from base density to e.g.

We enter pressure values for gas calculations. Are these values absolute or gauge pressure values?

QuantityWare BCS implementations for LPG/NGL, LNG and natural gas support both the data entry of absolute or gauge pressure values. Crude oil and products CPL calculations do require entry of gauge pressure values.

The conversion group configuration for LPG/NGL, LNG , natural gas, crude oil and products can thus be made to support data entry of either gauge or absolute pressure values – by adding or removing dedicated MQCI pressure calculation functions to the conversion group function module sequence.

I enter a vapor pressure value in bar, and it is converted to the value in kPa, why is that?

For pressure value data it is important to differentiate between absolute pressure values and gauge pressure values.

For all conversion groups, that are configured to require entry of pressure values, these values can either be a gauge or an absolute pressure value.

The behavior described in this FAQ question is defined within dedicated MQCI pressure conversion functions, that convert gauge pressure values to absolute pressure values – visible to the user and using the base pressure UoM as absolute (or vice versa).

If you do not require this behavior, you may replace the MQCI pressure conversion function with the corresponding function that treats all UoM as either all absolute or all gauge values,

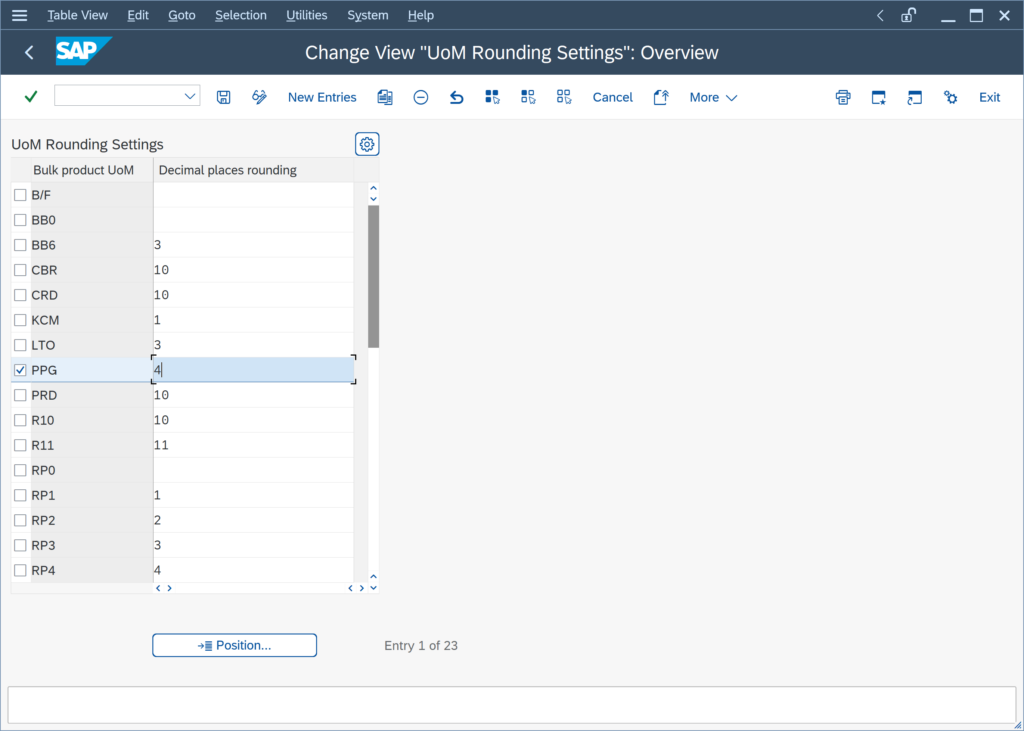

My rounding settings for the density values for an MQCI conversion group are not considered for the calculation. How can I fix this?

You have copied e.g. template conversion group Q1A1 to Z1A1. For the density UoM PPG (pounds per gallon – lb/ugl) you have maintained a rounding to 4 decimals; business requires that the rounded value is utilized for the calculation of masses.

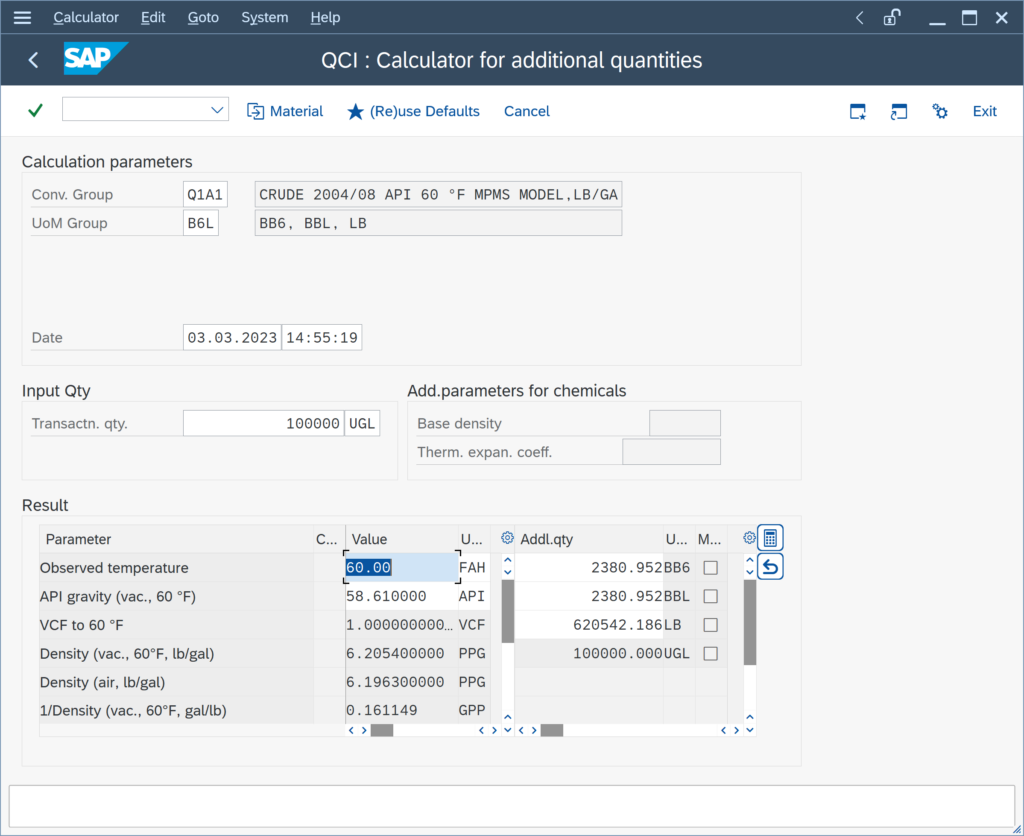

A simple test calculation with Q1A1 shows the issue: The expected value for UoM LB is 620 540.00 LB; however, the value is calculated using the non-rounded density (while the rounded value is displayed):

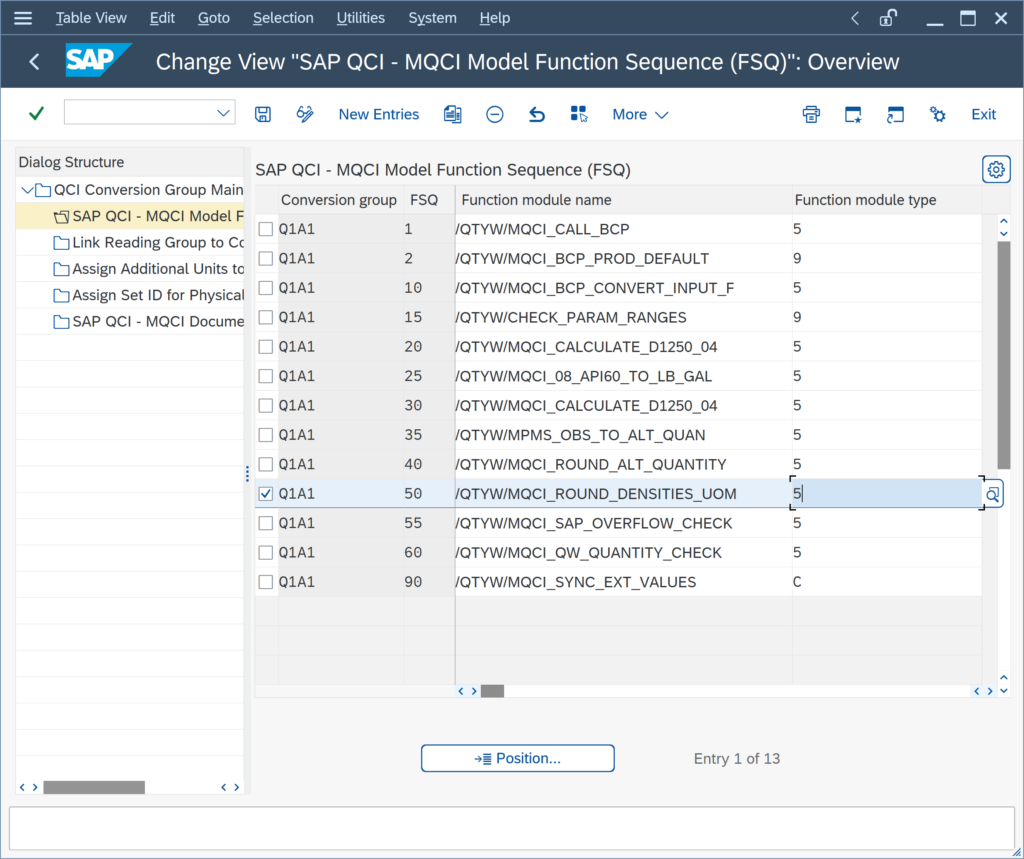

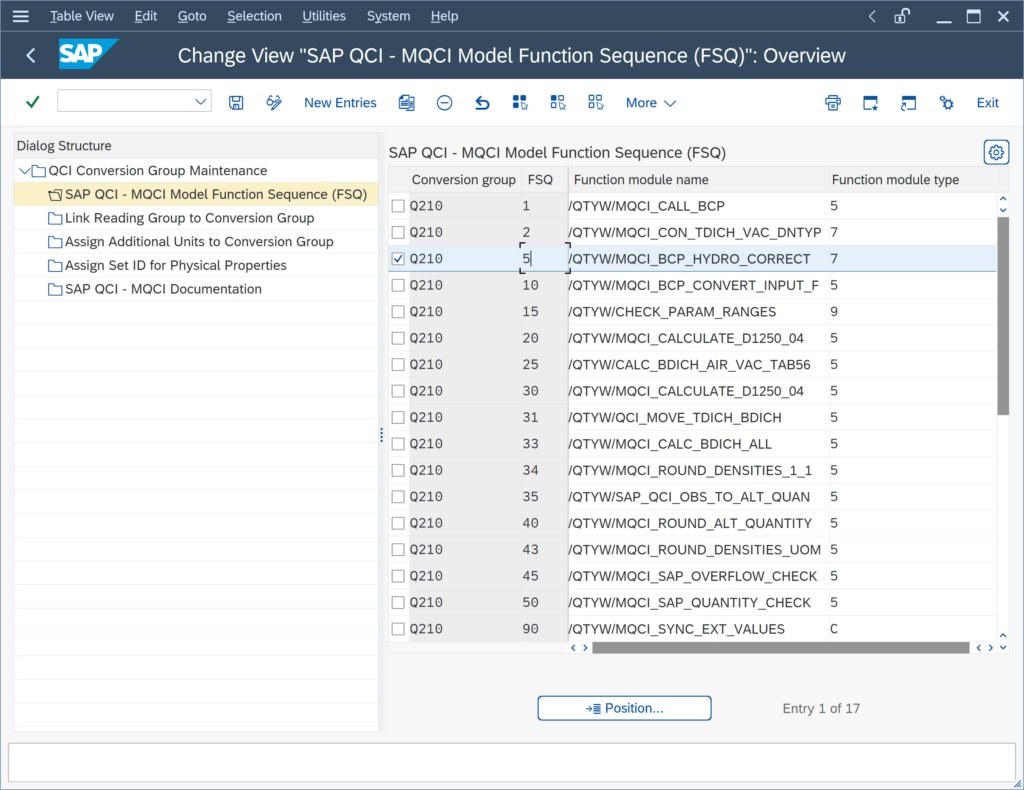

This is due to the fact, that the density rounding function /QTYW/MQCI_ROUND_DENSITIES_UOM is processed after the quantity conversion model function /QTYW/MPMS_OBS_TO_ALT_QUAN:

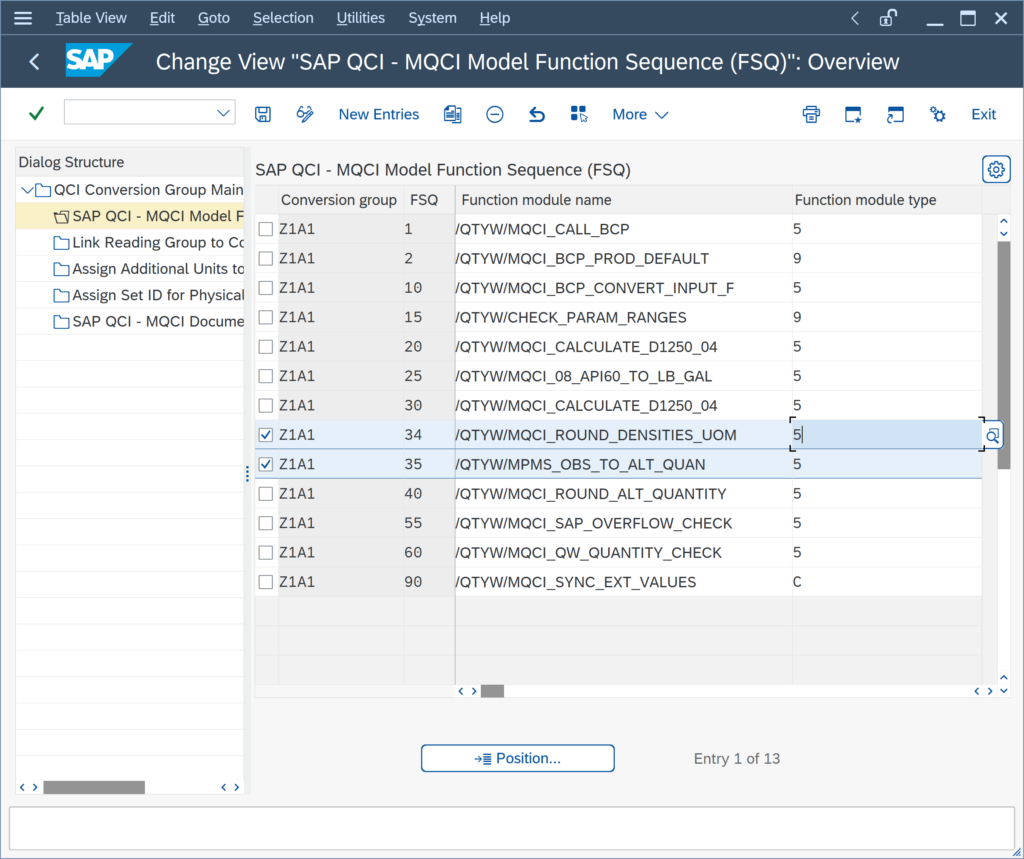

If you position the rounding function before the quantity conversion model function:

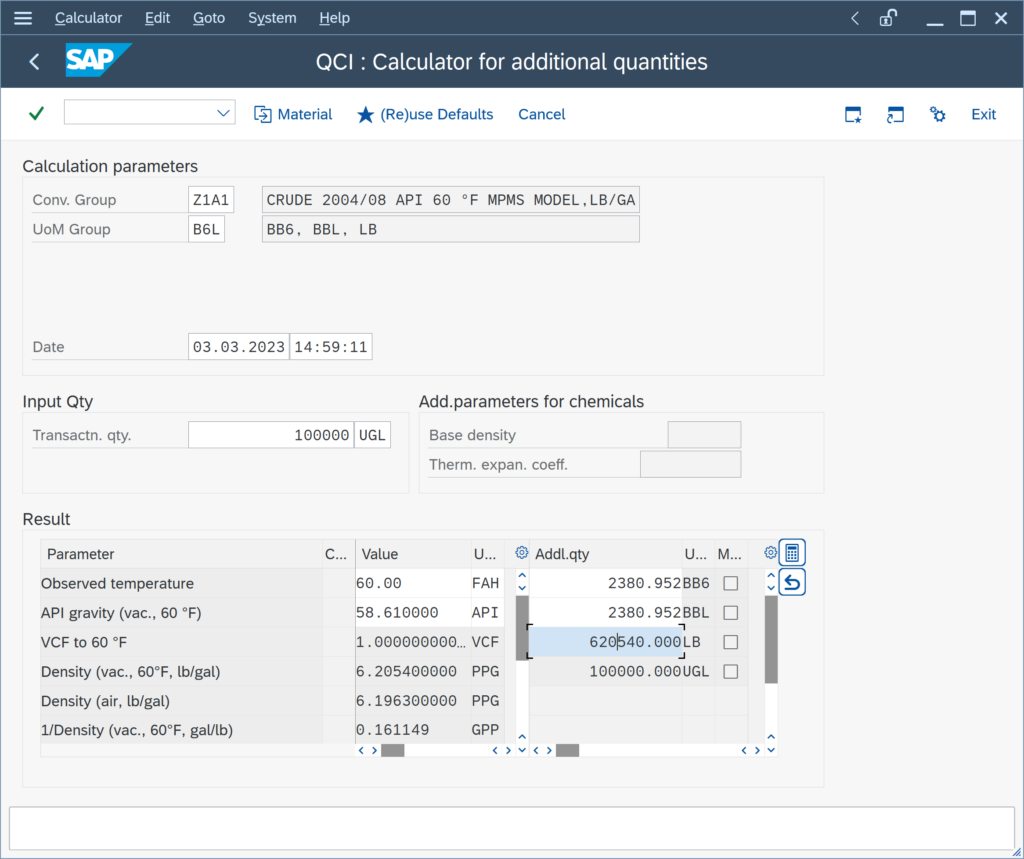

the calculation is happening as expected:

The Q*** template conversion groups are configured to round the density values for reporting purposes,

We do not require the hydrometer correction. Can we remove it from our conversion group configuration?

Yes.

The hydrometer correction may only be required, if you enter an observed density that is determined with a glass hydrometer. If you utilize an ASTM D1250-04 implementation, you may simply remove the hydrometer function (and also remove the hydrometer indicator from the reading group):

ASTM D1250-80 implementations contain a built-in (by measurement standard definition) hydrometer correction logic, which requires that you actively turn the correction off if it is not required – read note 000026 for all important details.

My client wants to use MQCI conversion groups, where UoM KG, LB, TO, STO ... are calculated as weights - is this possible?

Yes.

The BCS configuration template provides example MQCI conversion groups that are configured such that UoM of SAP dimension ID MASS are calculated as weights (which is also the case for SAP QCI conversion groups if the air buoyancy indicator is set).

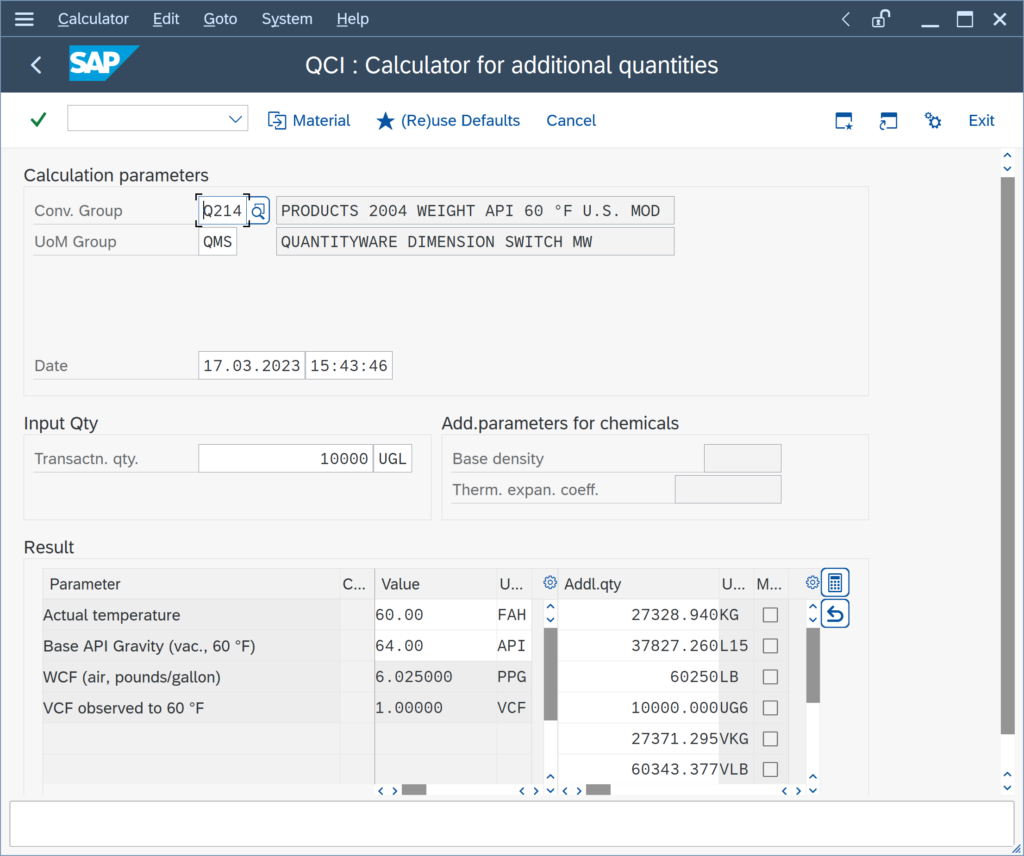

Example – BCP template conversion group Q214:

The LB value is the weight of the 10 000 gallons of product. The configuration to achieve this requires 2 (plus 1) steps:

Step 1:

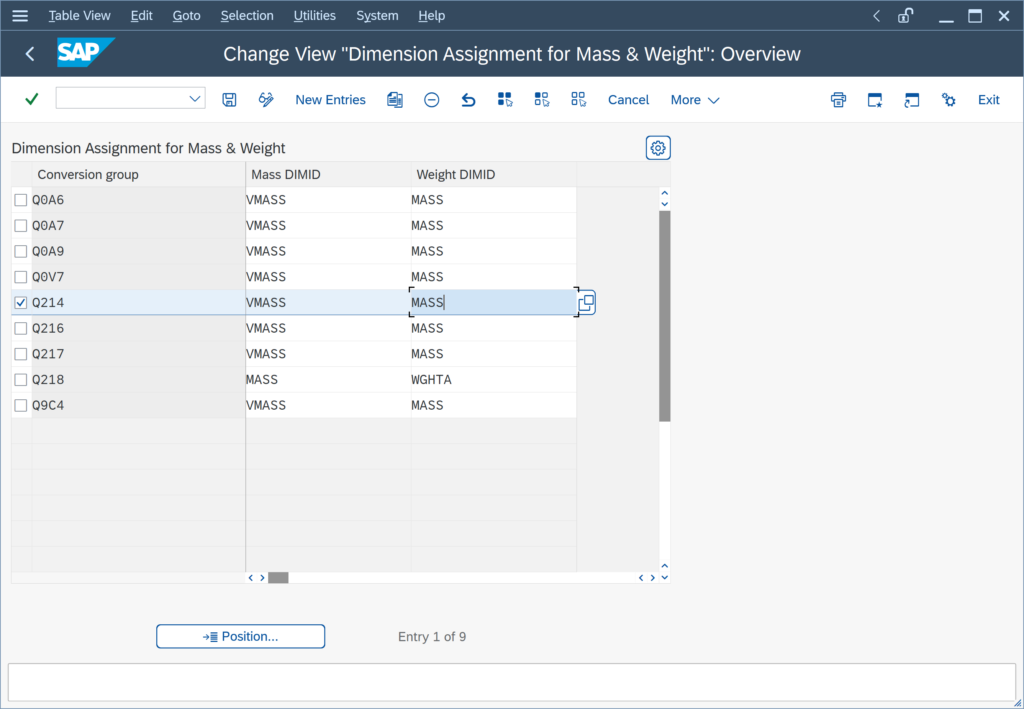

You assign the SAP Dimension IDs for weight (and mass) DIMID:

Step 2:

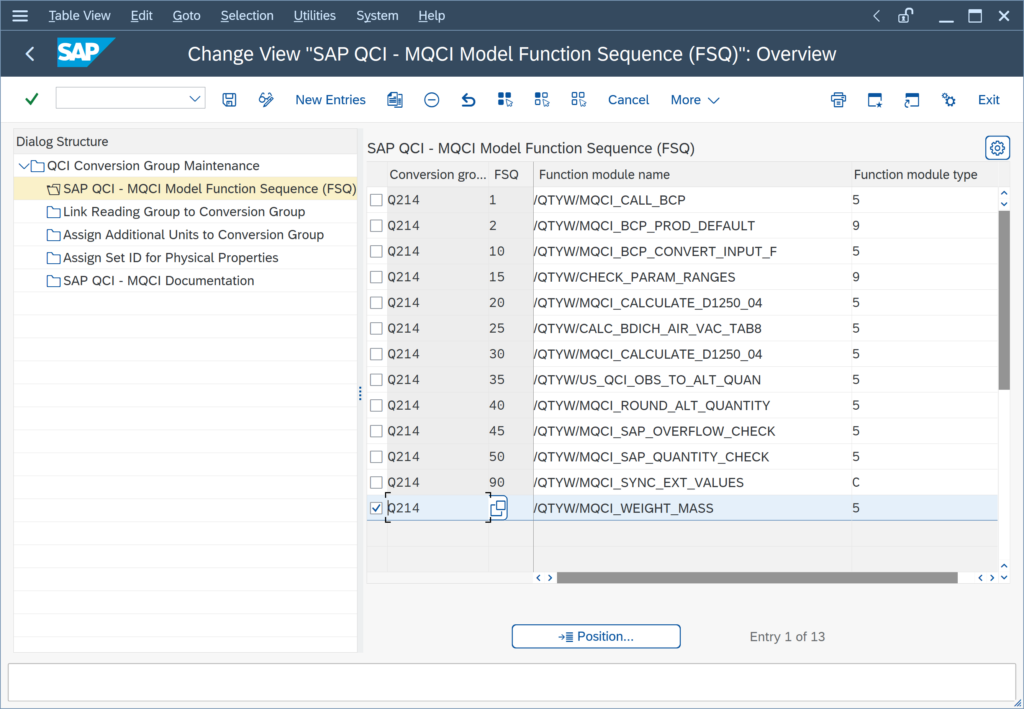

You assign marker function /QTYW/MQCI_WEIGHT_MASS to the MQCI model function sequence:

Step 3:

Depending on the MQCI calculation model,

My MQCI quantity conversion does not match the expected conversion factor between two units of the same dimension, how can this be?

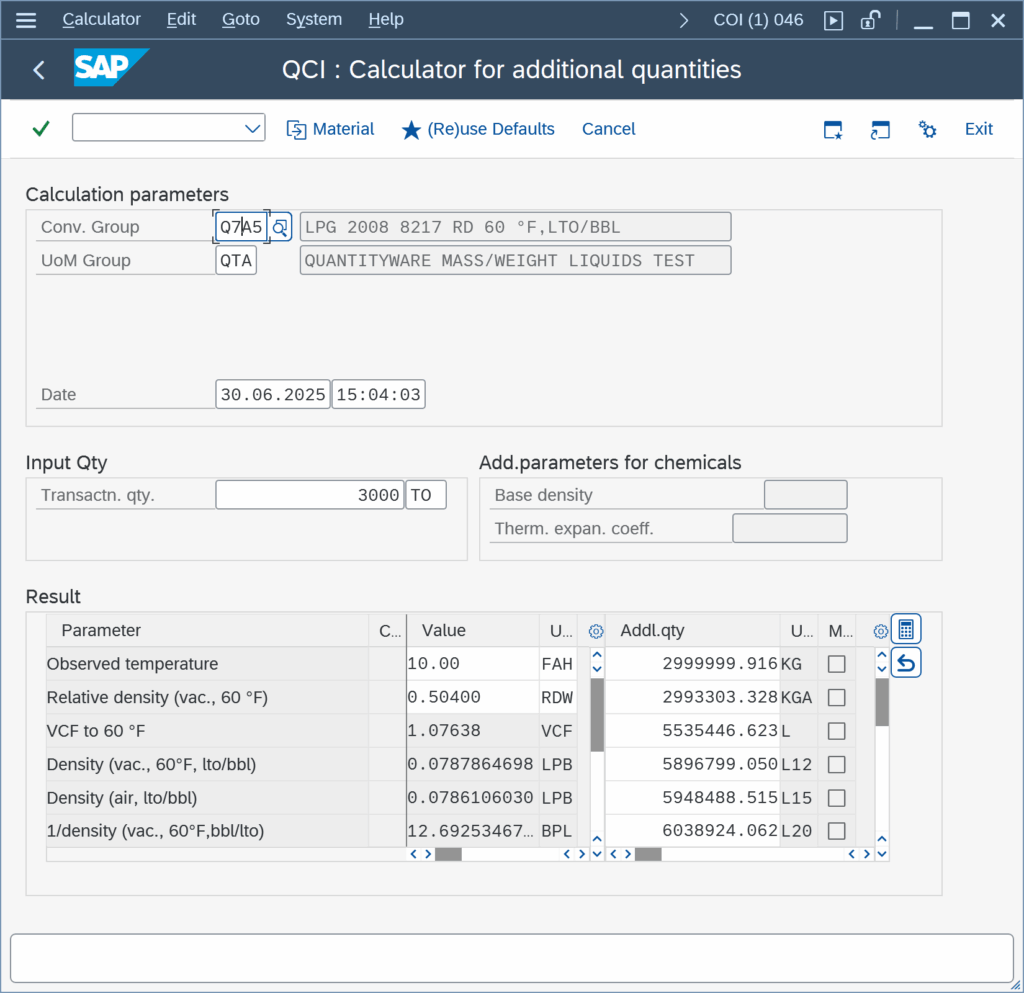

You perform a trial conversion for e.g. conversion group Q7A5:

The KG value is not calculated as 3 000 000 KG (as expected), but as displayed above, as 2 999 999.916 KG.

Explanation: The conversion group is configured to utilize a calculation model (read the BCP Documentation Reference Manual -> Chapter 6.5. for details) which uses LTO as base conversion UoM for masses. In addition, UoM conversion factors are defined with ASTM Table 1 conversion factors (or SAP CUNI if not defined).

When converting between TO and KG, two conversion calculations (TO to LTO and LTO to KG) are performed.

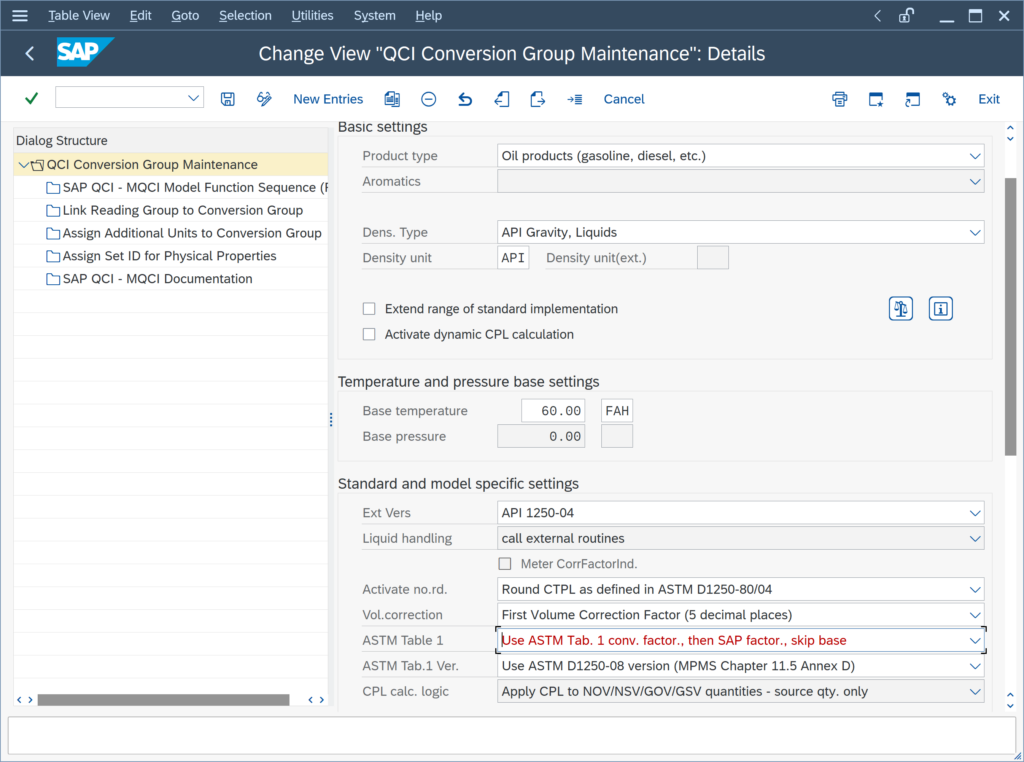

My customer requires ASTM Table 1 UoM conversion factors. What are the configuration steps?

For MQCI conversion groups, you simply activate the ASTM Table 1 conversion factors and ASTM Table 1 version in the conversion group detail settings:

With the QuantityWare BCS configuration templates, ASTM Table 1 conversion factors are delivered, which are accessible in your client 045 after activation of the relevant Business Configuration (BC) set. Read Note 000055 for all important additional configuration details.

What is MQCI function /QTYW/MQCI_SYNC_EXT_VALUES good for?

All QuantityWare MQCI template conversion groups are configured such that the MQCI function module sequence contains function

- /QTYW/MQCI_SYNC_EXT_VALUES

as default.

This function detects quantity value data that is passed from external systems (e.g. TAS systems) and subsequently synchronizes dependent quantity values based on that data.

If required, this synchronization may also be implemented for SAP QCI conversion groups via SAP QCI BAdI implementations at your own risk. Such a task should only be performed by a certified BCP consultant that is assigned to your implementation or renovation project.